Revolutionizing Metal Fabrication with High-Quality CNC Precision Machining Services

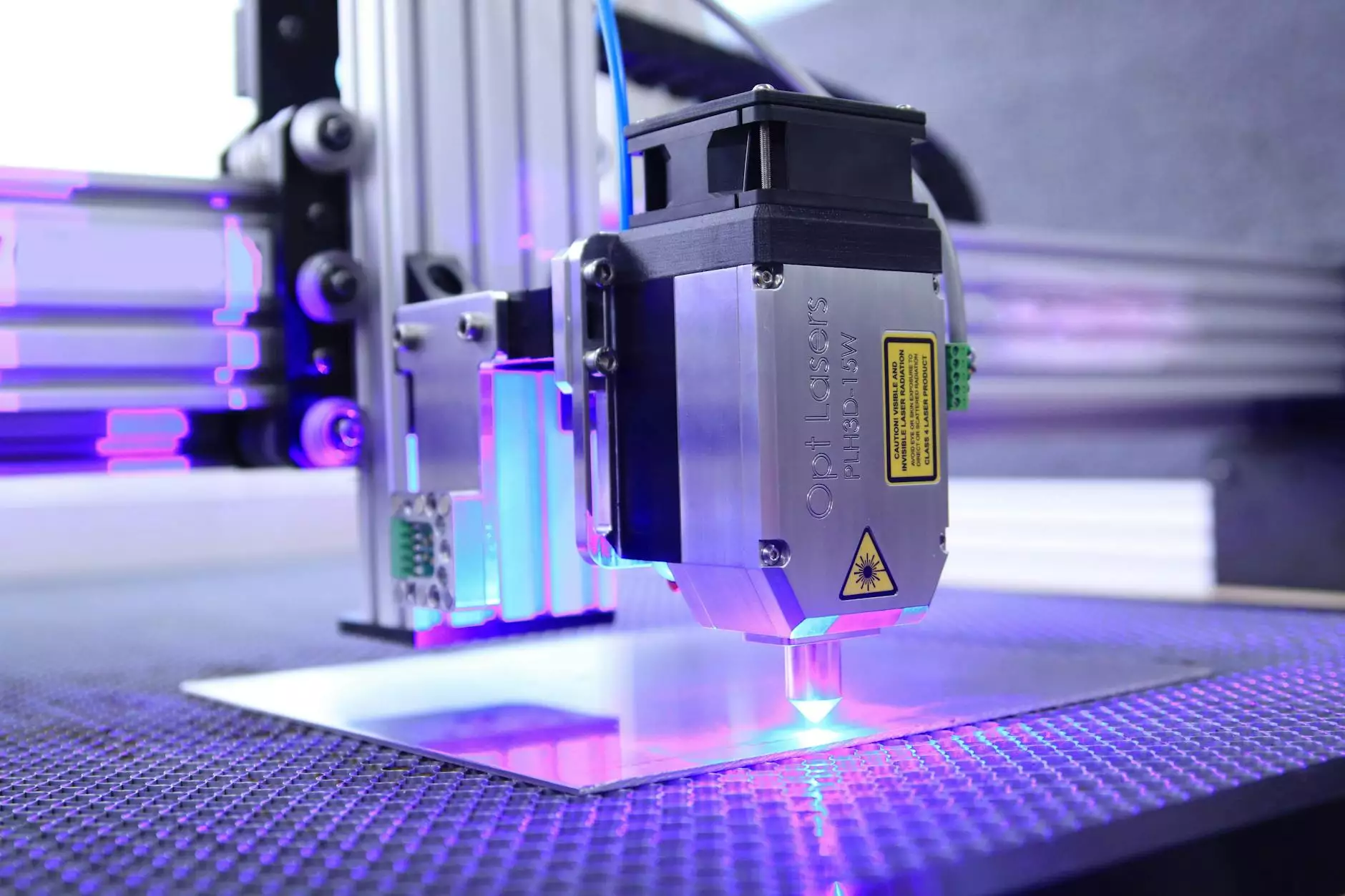

In the rapidly evolving world of manufacturing, the demand for precision, efficiency, and scalability has never been greater. Among the most innovative and effective solutions to meet this demand are cnc precision machining services. At DeepMould, our specialized CNC machining capabilities have positioned us as leaders in the metal fabrication industry, delivering unmatched quality and precision that empower businesses to achieve their manufacturing goals.

Understanding the Significance of CNC Precision Machining in Modern Metal Fabrication

CNC (Computer Numerical Control) precision machining represents the pinnacle of modern manufacturing technology. It involves computer-controlled tools executing complex cuts and shaping operations with extreme accuracy. This technology is vital for producing components that require tight tolerances, intricate geometries, and high repeatability—features indispensable across sectors such as aerospace, automotive, medical devices, and industrial machinery.

Our cnc precision machining services are characterized by.

- High Precision and Accuracy: Capable of achieving tolerances within microns, ensuring component consistency and performance.

- Complex Geometries: Able to produce intricate shapes and detailed features that traditional manufacturing methods cannot deliver.

- Enhanced Efficiency: Automated processes that reduce cycle times, minimize waste, and increase throughput.

- Versatility: Suitable for a wide range of metals including stainless steel, aluminum, brass, copper, titanium, and alloys.

Why Choose DeepMould for Your CNC Precision Machining Needs?

DeepMould stands out as a premier provider of cnc precision machining services with an unwavering commitment to quality, innovation, and customer satisfaction. Our facilities are equipped with state-of-the-art CNC machines and advanced software systems that enable us to tackle the most demanding projects with ease.

Comprehensive Metal Fabrication Solutions

We offer end-to-end metal fabrication services that encompass:

- Design Beratung: Collaborating with clients during the design phase to optimize manufacturability and cost-efficiency.

- Prototyping: Rapid prototyping capabilities that facilitate quick iterations and testing.

- Production: Mass production of precision-machined components with consistent quality.

- Assembly and Finishing: Additional services including surface treatment, anodizing, coating, and assembly.

All these services are executed with a focus on precision, durability, and aesthetics, ensuring your final product meets the highest standards.

Technological Edge and Innovation in Our CNC Machining Processes

At DeepMould, technological innovation is at the core of our operations. Our CNC machining centers are equipped with the latest multi-axis machines, allowing for complex, multi-step manufacturing processes in a single setup. This reduces the likelihood of errors and enhances efficiency.

Additionally, our advanced CAD/CAM software integration allows us to translate your digital designs into highly accurate machining programs automatically, minimizing manual intervention and ensuring fidelity to your specifications.

Automation and Quality Control

Precision is only achievable through rigorous quality control. Our facilities include comprehensive inspection tools such as coordinate measuring machines (CMM), laser scanners, and vision systems. These tools verify dimensions and surface quality at every critical stage.

We also employ automated feedback loops and data analysis to continuously optimize our processes, uphold micron-level tolerances, and reduce variability across batches.

Benefits of Choosing Professional CNC Precision Machining Services

Partnering with a trusted provider like DeepMould offers numerous advantages:

- Enhanced Product Quality: Achieve superior surface finishes and tight tolerances that meet or exceed industry standards.

- Cost Efficiency: Reduce material waste and machining time, thereby lowering overall production costs.

- Flexibility: Adapt to varying batch sizes, from prototyping to full-scale manufacturing.

- Speed to Market: Streamlined processes enable faster turnaround times, helping you stay ahead of your competitors.

- Customization: Tailor components to specific needs with precision and repeatability.

The Role of CNC Precision Machining in Business Growth and Innovation

In today's competitive landscape, leveraging cutting-edge cnc precision machining services can significantly impact your business growth. High-precision manufacturing can facilitate the development of innovative products, reduce lead times, and improve overall operational efficiency.

By integrating advanced CNC machining into your supply chain, your organization can:

- Accelerate Product Development: Rapid prototyping and testing enable quicker market entry.

- Improve Product Performance: Precisely machined parts ensure better fit, function, and longevity.

- Expand Design Possibilities: Complex geometries and intricate details open new creative avenues.

- Strengthen Competitive Edge: Consistent quality and innovative solutions differentiate your brand.

Choosing the Right Metal for CNC Machined Components

The selection of the appropriate material is crucial for achieving optimal performance and longevity of your CNC machined parts. DeepMould provides expertise across a broad spectrum of metals, each offering unique properties suitable for specific applications:

- Aluminum: Lightweight, corrosion-resistant, and easy to machine—ideal for aerospace, automotive, and consumer electronics.

- Stainless Steel: Exceptional strength, corrosion resistance, and durability for medical, food processing, and heavy-duty machinery.

- Brass and Copper: Excellent thermal and electrical conductivity—used in electronic components, decorative fixtures.

- Titanium: High strength-to-weight ratio, corrosion-resistant, suitable for aerospace, medical implants.

- Alloys: Custom-metal blends designed for specific strength, flexibility, or heat resistance requirements.

Ensuring Sustainability and Quality in CNC Metal Fabrication

Sustainable manufacturing practices are integral to modern CNC precision machining. DeepMould emphasizes environmentally responsible processes, including waste reduction, energy-efficient operations, and eco-friendly surface treatments. Simultaneously, quality is monitored meticulously to ensure each batch adheres to strict standards.

Our commitment to quality and sustainability not only benefits the environment but also enhances your brand reputation as a forward-thinking enterprise.

Partner with DeepMould — Your Trusted Metal Fabrication Expert

With years of experience and a dedication to technological excellence, DeepMould is your ideal partner for cnc precision machining services. Our expertise, state-of-the-art facilities, and customer-centric approach guarantee products that meet your specifications and business objectives.

Visit DeepMould.net to explore our comprehensive metal fabrication solutions, request a quote, or discuss your project needs. Our team is committed to transforming your ideas into high-quality, precision-engineered components that drive your business forward.

Conclusion: Embrace Precision for a Competitive Future

In an era where precision, efficiency, and innovation determine success, cnc precision machining services have become essential for any ambitious manufacturing enterprise. DeepMould’s dedication to excellence, technological innovation, and customer satisfaction positions us as the premier choice for metal fabrication needs.

Choose DeepMould today, and elevate your manufacturing capabilities with precision-engineered components crafted meticulously to propel your business into the future.