Boost Your Business with Laser Cutting Equipment

The Power Behind DP Laser's Laser Cutting Equipment

When it comes to precision metal fabrication, having the right tools is essential. DP Laser's innovative laser cutting equipment has quickly become the gold standard in the industry. With state-of-the-art technology and unparalleled accuracy, our machines can transform your metal fabricating business by streamlining operations, increasing productivity, and delivering exceptional results.

Unmatched Precision and Speed

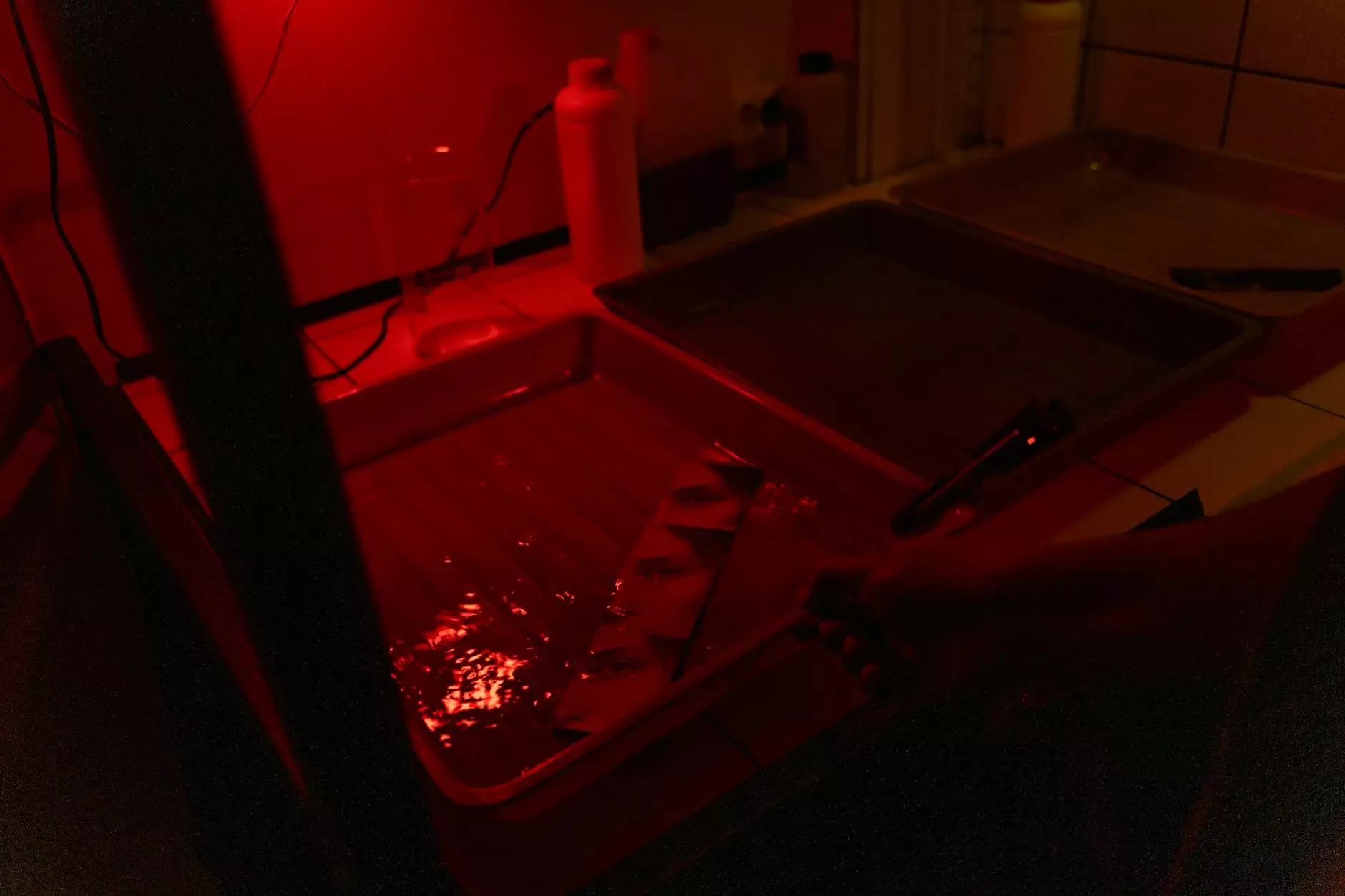

At DP Laser, we pride ourselves on the precision and speed of our laser cutting equipment. Our advanced laser systems use focused beams of light to melt, vaporize, or burn through materials, leaving precise and clean cuts behind. The high speed of our machines ensures efficient production times, allowing you to handle larger orders and meet tight deadlines.

The Benefits of Laser Cutting

- Superior Precision: Laser cutting offers unmatched accuracy, enabling you to achieve intricate and complex designs with ease. Say goodbye to imprecise manual cutting techniques and hello to clean, flawless edges.

- Versatility: Our laser cutting equipment is capable of handling various materials, including steel, aluminum, brass, and more. From delicate jewelry pieces to heavy-duty industrial parts, our machines deliver consistent results across a wide range of applications.

- Cost Efficiency: The precision and speed of laser cutting equipment translate to cost savings for your business. With minimal material waste and increased production speeds, you can achieve higher output with reduced operational costs.

- Minimal Post-Processing: Laser cutting significantly reduces the need for extensive post-processing. The clean cuts produced by our machines minimize the time and effort required for sanding, grinding, or smoothing rough edges, ultimately saving you precious time and resources.

- Enhanced Design Flexibility: Harness the power of laser cutting technology to unlock new design possibilities. With its high precision and ability to cut complex shapes effortlessly, you can let your creativity run wild and push the boundaries of what's possible.

Applications of Laser Cutting in Metal Fabrication

The applications of laser cutting in metal fabrication are virtually endless. Whether you operate a small workshop or a large-scale manufacturing facility, DP Laser's cutting-edge equipment can meet your diverse needs.

1. Sheet Metal Fabrication

From custom HVAC components to automobile parts, laser cutting is widely used in sheet metal fabrication. Our laser cutting machines excel at accurately cutting intricate patterns and shapes in various sheet metal thicknesses, helping you bring your designs to life efficiently and precisely.

2. Structural Steel

When it comes to the construction industry, laser cutting is indispensable for cutting and shaping structural steel elements like beams, columns, and trusses. The speed and precision of our laser systems make them ideal for handling large-scale projects with complex requirements.

3. Precision Engineering

Precision engineering demands the utmost accuracy and repeatability. With DP Laser's laser cutting equipment, you can produce high-quality components for industries such as aerospace, electronics, and medical devices. Whether you need micro-cutting or intricate engraving, our machines deliver consistent results with exceptional precision.

4. Decorative Metalwork

Laser cutting has revolutionized the world of decorative metalwork. From architectural elements to artistic sculptures, our laser cutting machines can turn your creative visions into stunning reality. Achieve intricate designs and precise detailing that will captivate your customers.

5. Prototype Development

Prototyping is an essential part of any manufacturing process. With DP Laser's laser cutting equipment, you can quickly and cost-effectively produce prototypes for a wide range of applications. Test and refine your designs before moving forward with full-scale production.

Why Choose DP Laser for Your Laser Cutting Equipment Needs

When it comes to investing in laser cutting equipment, quality, reliability, and industry expertise are of paramount importance. DP Laser stands out from the competition in multiple ways:

- Unrivaled Quality: At DP Laser, our commitment to excellence ensures that every machine leaving our facility meets the highest standards of quality and performance. You can rely on our equipment to deliver outstanding results, time and time again.

- Extensive Range: As a leading provider of laser cutting equipment, we offer a wide range of models to suit different business needs. From small-scale machines for startups to large industrial systems for high-volume production, our selection has something for everyone.

- Expert Support: Our team of experienced technicians is always ready to assist you with installation, training, and ongoing technical support. We believe in building long-term relationships with our customers and ensuring their success with our equipment.

- Continuous Innovation: DP Laser is committed to staying at the forefront of laser cutting technology. We continuously invest in research and development to bring you the latest advancements, allowing your business to stay ahead of the competition.

- Proven Track Record: With a solid reputation in the industry, DP Laser has helped numerous businesses like yours achieve remarkable growth and success. We let our track record speak for itself.

Take Your Metal Fabricating Business to New Heights with DP Laser

Don't let outdated cutting methods hold your business back. Embrace the power of laser cutting technology and unlock a world of possibilities for your metal fabrication business. With DP Laser's top-of-the-line equipment, superior precision, impressive speed, and wide-ranging applications are just the beginning.

Contact DP Laser today and let our experts guide you towards the perfect laser cutting solution tailored to your specific needs. Experience the DP Laser difference and propel your business to new heights in the world of metal fabrication.